OMRS to help curb major railway mishaps due to material failure

12 Dec 2019 10:39:57

By Sagar Mohod :

The on-line monitoring of rolling stock will help alert officials in advance in case of any problem in wheels n

CR’s General Manager Sanjeev Mittal likely to inspect OMRS during visit to Nagpur Division later this week

For enhancing safety on tracks, Indian Railways is installing a system for on-line monitoring of rolling stock (OMRS) in real time so as to pre-empt chances of any major mishap due to material failure. OMRS is basically aimed at monitoring health of wheels so that in case of any problem, an alarm is triggered helping alert the officials of impending issue that needs to be looked at forthwith.

An alarm is sounded about defective wheel condition through OMRS that basically works on acoustic, means after hearing any abject sound the control room would get notification about problem with wheel, informed Akhilesh Choubey, Sr. Divisional Mechanical Engineer, Central Railway, Nagpur Division while talking to ‘The Hitavada’. “At Nagpur Division, OMRS is installed on UP line at Borkhedi station. The advantage with Borkhedi is that it lies on trains that moves onto Southern as well as Western parts of the country,” Choubey informed. “Each of the set costs Rs 3.50 crore and it also has facility to trigger alert in case of hot axle. With OMRS, another advantage is that it also helps in sounding alarm about defective bearing that play major role in smooth movement of train coaches,” he added.

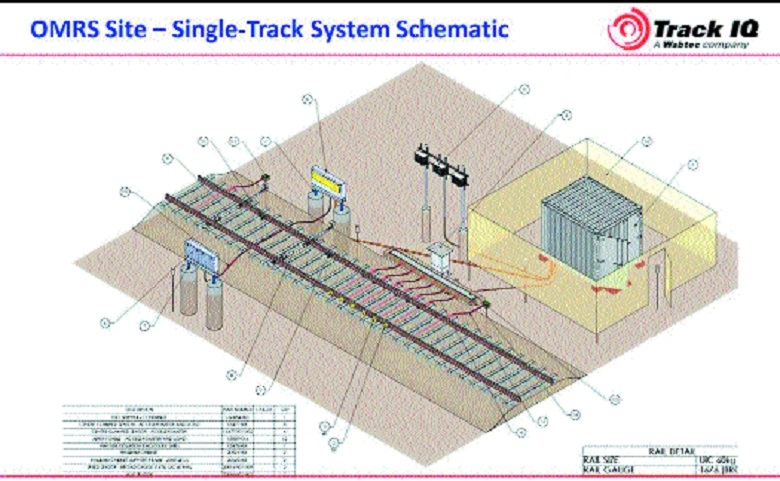

Providing more details, he said, “Throughout Indian Railways, OMRS is installed on 20 sites with 15 have single track circuits having facility of RailBAM, WILD (WCM) and Photo Tag/RFID. Five routes of Railways were chosen for double equipments sets, meaning covering UP and DN lines respectively, due to high volume of trains movement. “Equipment hut is installed on either side of the track that is enabled with RailBAM that's indicative of rail bearing acoustic monitor helping in early detection of would be failures of wheels. WCM is wheel condition monitor that works by measuring the vehicle's dynamic weight and also through impact (force) of wheel measurement (WILD).

“Photo TAG helps in identification of wagon whose wheel has developed a problem thereby resulting in savings of time. “Further within the hut, data analysis and processing, networking system in place. Once a train has rolled by the hut it would capture the data, analyse the same and relay it to control room at division and to Zone. The technology is developed by Australian company Track IQ and they have also set up a national control centre to provide back-up to Railways. The equipment hut are protected against power surge and also works under extreme temperature as they are fitted with air conditioning and are secured. They use RailTel’s OFC connectivity and also has wireless back-up.

“The acoustic sensors picks up abnormal sound through digital mikes installed by tack side and thereafter the same is processed in equipment hut and data is transferred to control room. Another mode of monitoring condition is high speed video footage that will identity the wheel that needs to be attended to,” Choubey said. Choubey added that General Manager Sanjeev Mittal would be inspecting the OMRS during his annual inspection visit to Nagpur Division later during the week.